NEWS CENTER

新闻中心

高熵合金涂层腐蚀性能研究进展

- 分类:十大玩彩信誉平台

- 作者:

- 来源:非晶合金

- 发布时间:2020-03-18

- 访问量:25

【十大信誉彩票平台】The research on the corrosion resistance of high entropy alloy coatings in recent years was summarized. The influences of preparation technology, alloy composition and process parameters on the corrosion resistance of high entropy alloy were investigated. The existing problems and key research points of high entropy alloy coatings were put forward。The authors of the above work are Jia Chuntang and Sha Minghong, College of Materials and Metallurgy, Liaoning University of Science and Technology。

高熵合金涂层腐蚀性能研究进展

【十大信誉彩票平台】The research on the corrosion resistance of high entropy alloy coatings in recent years was summarized. The influences of preparation technology, alloy composition and process parameters on the corrosion resistance of high entropy alloy were investigated. The existing problems and key research points of high entropy alloy coatings were put forward。The authors of the above work are Jia Chuntang and Sha Minghong, College of Materials and Metallurgy, Liaoning University of Science and Technology。

- 分类:十大玩彩信誉平台

- 作者:

- 来源:非晶合金

- 发布时间:2020-03-18

- 访问量:25

The research on the corrosion resistance of high entropy alloy coatings in recent years was summarized. The influences of preparation technology, alloy composition and process parameters on the corrosion resistance of high entropy alloy were investigated. The existing problems and key research points of high entropy alloy coatings were put forward。The authors of the above work are Jia Chuntang and Sha Minghong, College of Materials and Metallurgy, Liaoning University of Science and Technology。

The lack of high temperature stability of most conventional alloys reduces their mechanical properties and corrosion resistance, thus limiting their application in extreme and highly sensitive engineering environments。In 2004, Yeh et al. broke through the traditional concept of alloy design and proposed the concept of high entropy alloy (HEAs), which was initially defined as a new alloy containing more than 5 major elements and the content of each major element between 5% and 35% (atomic fraction)。Due to the effect of high mixing entropy, high entropy alloys tend to form simple solid solution structures such as face-centered cubic (FCC), body-centered cubic (BCC) or close-packed hexagonal (HCP) structures rather than complex intermetallic compounds。The special composition and structure make the high entropy alloy both heat resistance, wear resistance, corrosion resistance and good magnetic properties。Therefore, high-entropy alloys are expected to become candidate materials for some extreme and highly sensitive engineering environments such as nuclear power, turbine engines and aerospace。

Because they contain many expensive metals (e.g. Nb, W, Cr, V, Ni, Ti, etc.), high entropy alloys can cost more than most conventional alloys, and the use of surface coatings can solve this problem。In recent years, researchers have successfully prepared high entropy alloy coatings by laser cladding, EDM deposition, electrochemical deposition, electron beam evaporation, magnetron sputtering and other processes。By using a high entropy alloy coating, a reasonable combination of cost and performance can be achieved。

01

高熵合金涂层的耐蚀机理

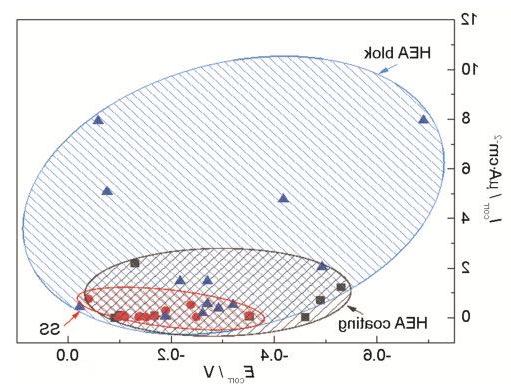

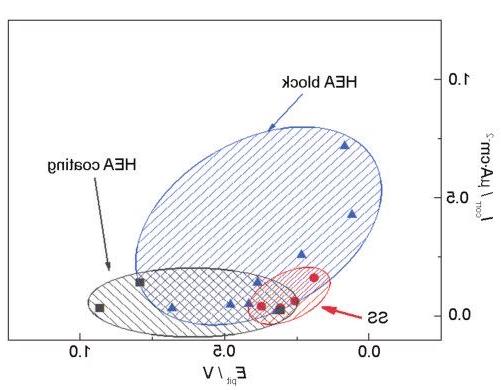

Figure 1 shows the high entropy alloy coating, block high entropy alloy and stainless steel in 3.Corrosion behavior diagram in 5% (mass fraction) NaCl solution。It can be seen from the figure that compared with the bulk high-entropy alloy, the high-entropy alloy coating has a lower current density (I corr) and a higher corrosion potential (E corr), and the corrosion resistance is similar to that of stainless steel。Figure 2 shows the high entropy alloy coating, block high entropy alloy and stainless steel in 3.5% (质量分数) NaCl的点蚀行为图。It can be seen that the high entropy alloy coating has lower corrosion resistance and higher pitting potential (E pit). Compared with stainless steel and bulk high entropy alloy, the high entropy alloy coating shows better pitting resistance。

Figure 1 High entropy alloy coating, block high entropy alloy and stainless steel in 3.5%NaCl溶液中的腐蚀行为

Figure 2 High entropy alloy coating, block high entropy alloy and stainless steel in 3.5%NaCl溶液中的点蚀行为

高熵合金的耐蚀机理可以概括为以下3点:

(1) Due to the influence of high entropy effect, high entropy alloys are easier to form a single solid solution phase or amorphous phase than traditional alloys。众所周知,相组成越单一,成分越均匀。The formation of a single solid solution or amorphous can reduce the role of galvanic corrosion and the number of microcells, thereby improving corrosion resistance。

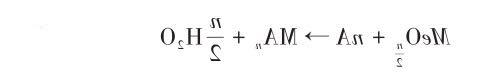

(2) The addition of Cr, Ni, Cu, Ti and Mo elements can produce passivation film on the surface of the coating。In oxidizing acids such as nitric acid and concentrated sulfuric acid, these elements are easily oxidized to form dense oxide films, such as Al2O3、CrO3、Cr2O3膜等,从而降低了腐蚀速率。In alkaline solution, the surface of the alloy with corrosion resistance elements is easy to interact with OH-Form hard-to-dissolve hydroxides that gather on the surface of the alloy to form dense passivation films, such as Al(OH)3、Cu(OH)2The polarization reaction is effectively inhibited by the film, which slows down the corrosion rate and improves the corrosion resistance of the alloy。In addition, water can also promote the formation of passivation film, it is generally believed that the following reactions are carried out during the passivation process of metal surface:

其中,(MeOH)ad是中间产物,n是金属离子的价数。如果溶液中含有易破坏钝化膜的负离子A-(如Cl-),则会与钝化膜发生下列反应:

因此,Cl-It can destroy the passivation film and produce pitting corrosion. Studies have shown that the appropriate addition of Mo can produce a passivation film with self-healing function with Cr, and can effectively inhibit Cl-造成的点蚀。In addition, it has been shown that since Me-N bonding is more chemically inert than Me-Me bonding, the participation of N helps to improve the corrosion resistance of high-entropy alloy coatings。

(3) Compared with bulk high-entropy alloys, more uniform microstructure can be obtained in the coating of high-entropy alloys。Due to the rapid quenching effect during the preparation process, the diffusion of elements in the high-entropy alloy coating can be more effectively inhibited, thus achieving a more uniform composition distribution and improving corrosion resistance。

02

2.1 激光熔覆技术

Laser cladding technology is a rapidly developing surface treatment method with a fast cooling rate (103~106K/s)的特点,能够避免成分偏析。The technology can be used to manufacture a high-entropy alloy coating with a thickness of about 1 to 5 mm, which is much thicker than the film prepared by magnetron sputtering。Laser cladding creates a metallurgical bond between the coating and the substrate, which is stronger than the bond obtained by thermal spraying technology。Zhang et al. used laser cladding technology to prepare FECo-Cralni high-entropy alloy coating on 304 stainless steel surface. The results showed that the coating was produced at a concentration of 3.In 5%NaCl solution, FeCoCrAlNi high-entropy alloy coating showed better corrosion resistance and pitting resistance than 304 stainless steel。Ye et al. used electrochemical workstation to study the corrosion resistance of laser-coated CrMnFeCoNi high-entropy alloy coating and found that the corrosion resistance of the high-entropy alloy coating was better than that of 304 stainless steel。

2.2 磁控溅射技术

Magnetron sputtering is the most commonly used technology for preparing high entropy alloy thin films。During sputtering, the stoichiometry of high entropy alloy films can be easily controlled by changing the chemical composition and process parameters of the target。Li et al. prepared the Fealcu-Crcomn high-entropy alloy coating by magnetron sputtering technology. Electrochemical experiments show that the Fealcu-Crcomn high-entropy alloy coating has a low temperature of 3.5%NaCl、5%NaOH、10%H2SO4The corrosion resistance of the solution is better than that of 201 stainless steel, in addition to the preparation of FeAlCoCuNiV coating, which also has better corrosion resistance than 201 stainless steel。The corrosion properties of high entropy alloy coatings prepared by magnetron sputtering have not been widely studied at present, but because of the homogenization effect and satisfactory corrosion resistance of magnetron sputtering, the study of high entropy alloy coatings prepared by magnetron sputtering will become a hot spot。

2.3 电火花沉积技术

Edm deposition is an energy saving, material saving, environmental protection emerging material surface treatment technology, it is the use of high current short pulse electrode material deposited on the substrate metal surface, trace electrode material melting under the action of pulsed plasma arc, and quickly solidified on the substrate surface to form a coating。Li et al. prepared AlCoCrFeNi high-entropy alloy coating on AISI 1045 carbon steel by electrospark deposition, which was combined with AlCoCrFeNi high-entropy alloy cast by copper mold in 2.Corrosion behavior in 5% (mass fraction) NaCl solution was compared,It is found that the corrosion current of coated samples is significantly lower than that of cast AlCoCrFeNi high entropy alloy,This is due to high entropy alloys compared to casting AlCoCrFeNi,The Al-CocrFENi high entropy alloy coating has a relatively high content of Cr oxides and Al oxides on the surface,而且不存在富含Cr的枝晶间相和第二相沉淀,不会产生电偶腐蚀。

2.4 其他制备技术

Plasma arc cladding has many advantages in the preparation of high entropy alloy coatings, such as high energy exchange efficiency, low thermal distortion of parts and low dilution of matrix materials。Cheng et al. prepared CoCrCuFeNi high-entropy alloy coating by plasma arc cladding process. The experiment shows that the corrosion resistance of CoCrCuFeNi high-entropy alloy coating in 6mol/LNaCl solution is better than that of 304 stainless steel。Ge et al. prepared CuZrAl‐TiNi high entropy alloy coating on T10 matrix by mechanical alloying and vacuum hot pressing sintering technology,与T10基体相比,The corrosion resistance of CuZrAlTiNi high entropy alloy coating in seawater solution is greatly improved,The main manifestations are high corrosion potential, wide passivation area and secondary passivation。Niu等采用电子束蒸发法将AlxFeCoCrNiCu(x=0.25,0.5,1.0) The high entropy alloy coating is deposited on the alloy steel matrix composed of the same alloying elements. The electrochemical experiment results show that Al0.5FeCoCrNiCu高熵合金涂层在H2SO4The passivation zone in NaCl solution is greater than 700mV, and has a high corrosion potential (-129mV) and a small corrosion current density (≈2).2×10-6A/cm2),这些结果表明Al0.5The corrosion resistance of FeCoCrNiCu coating is better than that of unmodified substrate。

3.1 Al

Ye等研究了Al的添加对AlxFeCoCrNiCuCr(x=1,1.3,1.5,1.8) 高熵合金涂层在0.Electrochemical experiments show that adding Al improves the corrosion resistance of the coating, and the corrosion resistance of Al x FeCoNiCrTi coating is better than that of 314 L stainless steel, in which Al 1.8 FeCoNiCuCr的耐蚀效果最佳。Niu et Al studied the effect of Al on Alx FeCoCrNiCu(x=0).25,0.5,1.0) The high entropy alloy coating is respectively at a concentration of 1 mol/L H2 SO4The effect of corrosion resistance in solution and 1 mol/L HCl solution was studied at a concentration of 1 mol/LH2SO4溶液中,当Al含量低于0.When the Al content is 5, it shows good corrosion resistance and pitting resistance, but when the Al content is 1.At 0, the corrosion resistance and pitting resistance are reduced, but it is still better than 304 stainless steel。在1 mol/L NaCl溶液中,Al1.0FeCoCrNi‐Cu的耐点蚀能力优于Al0.5FeCoCrNiCu high entropy alloy coating, 304 stainless steel has the worst pitting resistance。

3.2 Ti

Qiu等研究了Ti对 Al2CrFeNiCoCuTix(x=0,0.5,1.0,1.5,2.0)高熵合金涂层的影响。与Q235钢相比,Al2CrFeNiCoCuTixThe self-corrosion current density of the high-entropy alloy coating is reduced by 1~2 orders of magnitude, and the self-corrosion potential is more "positive".。With the increase of Ti content, Al2CrFeCoCuNiTix high entropy alloy coating decreased to 0.5mol/LHNO3溶液中的耐蚀性提高。石海等制备了Ni1.5Co1.5FeCrTixHigh entropy alloy coating, the study shows that with the increase of Ti content, Ni1.5Co1.5FeCrTix高熵合金涂层在0.5mol/LHNO3溶液中的耐蚀性得到提高,这是因为Ni1.5Co1.5FeCrTix高熵合金涂层表面在HNO3溶液中容易形成致密的钝化膜。

3.3 Ni

Qiu等研究了Ni含量对Al2CrFeCoCuTiNix(x=0,0.5,,1.0,1.5,2.0) High entropy alloy coating in 1mol/LNaOH solution and 3, respectively.Corrosion behavior in 5%NaCl solution, experiments show that with the increase of Ni content, Al2CrFeCoCuTiNix高熵合金的耐腐蚀性先上升后下降,其中Al2CrFeCoCuTiNi1.0具有最佳的耐腐蚀性。The reason can be attributed to: Ni element has a strong corrosion resistance, but its atomic radius is relatively small, when the Ni content is high, the lattice distortion of the alloy becomes serious, thus affecting the microstructure of the alloy, and then affecting the corrosion resistance of the alloy。Wu等研究了FeCoCrAlCuNix(x=0.5,1.0,1.5)高熵合金涂层在3.In 5%NaCl solution, the corrosion resistance also showed a trend of first increasing and then decreasing with the addition of Ni, among which Fe‐CoCrAlCuNi1.0耐蚀效果最佳。

3.4 Mo

Li Dongliang et al. studied the effect of Mo content on FeCrNiMnMoxB0.5(x=0,0.4,0.8,1.0) The effect of high entropy alloy coating on microstructure properties was found to be FeCrNiMn‐Mo in saturated saline slurry solution0.4B0.5The corrosion resistance is the best, which is due to the passivation film formed by Mo and Cr, which obstructs Cl-的侵蚀。When Mo increases further, Mo accumulates in grain boundaries, resulting in uneven coating composition and decreased corrosion resistance。

3.5 其他元素

Cai等研究了Cu对FeCoCrNiCuxThe study shows that the addition of Cu will reduce the passivation ability of the cladding layer and make the corrosion resistance of the alloy worse。The reason can be attributed to the addition of Cu will segregate Cu in the grain boundary to form a Cu-rich phase, resulting in galvanic corrosion, so that the corrosion resistance of the cladding layer decreases。Cheng et al. studied the effect of Nb on the corrosion resistance of the high-entropy alloy coating, and the study showed that the impedance coefficient of the coating containing Nb was 14 times and 1 times that of 304 stainless steel and non-Nb coating, respectively.6 times, which indicates that the addition of Nb element will improve the corrosion resistance of the coating 。Qiu等研究了Co含量对Al2CrFeCoxThe effect of CuNiTi high entropy alloy coating on corrosion resistance was found that with the increase of Co content, Al2CrFeCoxCuNiTi high entropy alloy coating in HCl and H2SO4溶液中的耐蚀性增强。This is due to the participation of Co to form a dense passivation film on the surface of the alloy。Zhang et al. prepared FeCrNiCoB by laser claddingx涂层。当0.5<x<1.At 0, the corrosion resistance of the coating is improved with the increase of B content。当x接近1.25时,硼化物从斜方晶系(Cr,Fe)2B转变为四方晶系(Fe,Cr)2B, this will reduce the corrosion resistance of the coating, but still show better corrosion resistance than ASTM304L stainless steel。

Qiu et al studied the effect of scanning rate on the corrosion resistance of laser cladding Alcrfe-Cuco high entropy alloy, and the experiment showed that with the increase of scanning rate, the corrosion resistance of the alloy first increased and then decreased。This is because under the action of fast heating and fast cooling of the laser beam, the microstructure of the coating becomes fine and uniform, the component segregation is reduced, and the corrosion resistance is improved。When the scanning rate is too fast, the convection increases, the surface of the cladding is rough, and the corrosion resistance deteriorates。

Shon et al. studied the influence of energy input and the number of cladding layers on the corrosion behavior of laser cladding CoCrFeNi coating. The study showed that the combination of higher energy input and double-layer cladding can reduce the dilution of the substrate to the coating, thus avoiding the formation of local galvanic cells, and reduce the corrosion behavior of Cocrfeni coating in 3.5%NaCl溶液中表现出了优异的耐腐蚀性。

Hsueh et al studied the effect of substrate bias on the corrosion resistance of DC reactive magnetron sputtering (AlCrSiTiZr)N high-entropy alloy coating。It has been shown that the substrate bias of -100V can effectively improve the corrosion resistance of (al-crsitizr)N amorphous films, which is caused by the densification and compressive stress of the films caused by the substrate bias。

Shi Yanyan et al. studied the influence of different substrate temperatures on the corrosion resistance of magnetron sputtered FeNiCoCrMn high-entropy alloy films. The study showed that as the substrate temperature increased, the thickness of the films gradually decreased and the corrosion resistance decreased, among which the corrosion resistance of the films deposited at 100℃ was the best。

过去的14年中,Research on high-entropy alloys has opened up a vast, untapped field of multi-component alloys,High entropy alloys are expected to show potential in various engineering environments due to their excellent properties,In this paper, the research progress and corrosion resistance mechanism of high entropy alloy corrosion resistant coatings are summarized from three aspects: preparation technology, alloying elements and technological parameters,为了对高熵合金耐蚀性进行更深入的研究,推动高熵合金应用于实际工业生产中,对未来的研究建议如下:

(1) Current research results on passivation films mainly provide microscopic characterization, and cannot explain the root cause of high entropy alloys with high corrosion resistance。Therefore, it is necessary to conduct high-resolution analysis of the high entropy alloy passivation film and further study on the corrosion resistance mechanism。

(2) The study of microstructure of high entropy alloy still stays in the "trial and error" stage, which not only causes low efficiency, but also increases the cost of scientific research。Therefore, it is one of the future research directions to start the material genome project, design cluster structures by first principles and ab initio molecular dynamics simulation, and perform equilibrium and non-equilibrium thermodynamic calculations for high-entropy alloy coatings to predict phase formation and transition。

(3) The stable process system for preparing high-quality high-entropy alloy coatings has not been established. Therefore, how to obtain uniform microstructure, reproducibility and guiding significance of coating preparation process will be one of the main research directions for the application of corrosion-resistant high-entropy alloy coatings。

扫二维码用手机看

- 业务咨询

- 咨询电话 023-67787593

- 返回顶部

服务热线:

传真:023-67787596

网址:scottsbluff.seamslikemagik.com

邮箱:info@seamslikemagik.com

Address: No.66 and No.180, Area c, Sendi Avenue, Jiulongpo District, Chongqing

Copyright © 2020 Chongqing Dayou Surface Technology Co., LTD. All Right Reserved 渝ICP备16005686号

Copyright © 2020 Chongqing Dayou Surface Technology Co., LTD

渝ICP备16005686号